Kutaura zvazviri, iyi ndiyo mamiriro ezvinhu akajairika apo simbi inotsika inofa inoputika, asi kana kuputika kwakanyanyisa, kunoputika kuita zvidimbu zvakawanda.Pane zvikonzero zvakawanda zvinotungamira kuputika kwesimbi stamping template.Kubva kutenga mbishi zvinhu nokuda simbi stamping kufa kuti simbi stamping oparesheni muitiro, zvingava chikonzero kuputika simbi stamping kufa.

1. Kufuga-vhara kusingagutsi

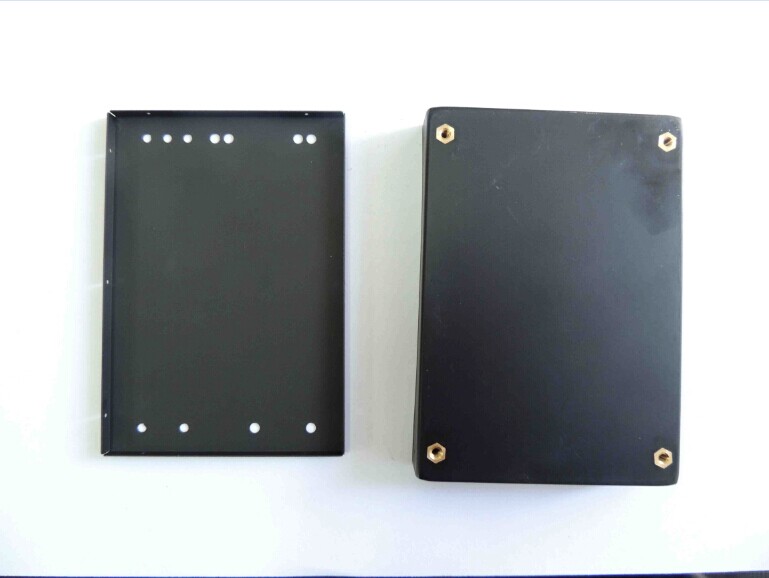

Iko hakuna demagnetization mhinduro isati yagadzirwa uye kugadzira, uye hapana ejection zano;Pane zvakanamira zvinhu zvakaita setsono yakatsemuka, chitubu chakatyoka uye yero mukugadzirwa;Zvinonyanya kuzivikanwa kuti hapana kubuda tsvina, kana kukunguruka kwetsvina, kana tsoka yetsvina pakuunganidza mold.Kana mudzidzisi anounganidza mold akasateerera, senge paine maburi akawanda akavharika, kana kana simbi yekutsikisa mold ine inodzivirira layer cushion block, iyi mamiriro angangoitika.

2. Design scheme Processing teknolojia

The compressive simba resimbi stamping inofahaina kukwana, kupatsanurwa kwemaronda kuri padyo zvakanyanya, dhizaini yesimbi yekutsikisa dhizaini haisi yesainzi, uye nhamba yematemplate haina kukwana pasina cushion blocks.

3. Kudzima uye kudzikamisa kurapwa: deformation inokonzerwa nekushaya kupisa kurapwa uye kudzima maitiro

Chiitiko chinoshanda chinoratidza kuti kupisa kwemhando yesimbi stamping inofa inokuvadza zvakanyanya kune hunhu uye hupenyu hwesevhisi yesimbi stamping inofa.Maererano nekuongorora uye kuongororwa kwenhamba yezvikonzero zvekusashanda kwesimbi stamping inofa, "njodzi yekuchengeteka" inokonzerwa nekuregeredza kwekushisa inosvika 40%.

4. Mutsara wekucheka kuregeredza

Iyo pasi waya yekucheka uye waya yekucheka gap inogadziriswa zvisizvo, uye kona yekuchenesa uye mildew layer kukuvadzwa kunokonzerwa nekucheka kwewaya hakuitwe.Iyo metal stamping die tooth surface inonyanya kugadziriswa nekucheka kwewaya.Nekuda kweiyo thermoelectric mhedzisiro uye electrolysis mhedzisiro yekucheka waya, iyo pamusoro pesimbi yekutsikirira kufa yekugadzira inofanirwa kuve yakatetepa uye yakakora, zvichikonzera kudzikiswa kwesimba repamusoro, kutaridzika kwekutsemuka kwemaikorosikopu, nezvimwe, zvichikonzera kukuvara kwekutanga kweiyo. metal stamping die yakagadziriswa nekucheka kwewaya, nekukasira kuisa mungozi kuchengetwa kweiyo inotonhora yekutsika gaka resimbi stamping kufa uye zino repamusoro riri nyore kutsemuka, kuderedza hupenyu hwesevhisi yesimbi inotsika kufa.Naizvozvo, mukuita kwekucheka kwepamhepo, geji remagetsi rinoshanda rinofanira kusarudzwa kuti udzivise kudzika kwakadzika kwehutu.

5. Kugamuchirwa kwepamusoro-speed punch machine equipment

Tonnage ye-high-speed punch, kusakwana kutonhora kwekumanikidza, uye kugadzirisa mold inogona kunge yakadzika.Iko kurongeka uye kuomarara kwematurusi emuchina wekutsikisa (sekutsikirira) kwakakosha zvakanyanya kuhupenyu hwesimbi inofa.Muchina wekutsikisa une yakanyanya kurongeka uye kuomarara kwakanaka, uye hupenyu hwesevhisi yesimbi inodhinda inofa yakagadziridzwa zvakanyanya.Semuenzaniso, iyo mbishi yedhizaini inofa kune yakaoma ferrite core hardware ndeye Crl2MoV, iyo inoshandiswa pane yakavhurika yemhando punch, uye avhareji yehupenyu hwebasa regrinding i1-3 miriyoni nguva;Hupenyu hwesevhisi yesimbi inodhinda kufa inogona kusvika 6-12.

Nguva yekutumira: Nov-18-2022