Jekiseni mold polishing ine zvinangwa zviviri;Imwe ndeyekuwedzera kutsetseka kwemuumbi, kuitira kuti pamusoro pezvigadzirwa zvinogadzirwa nehuturu zvive zvakanaka, zvakanaka uye zvakanaka.Imwe yacho ndeyekuita kuti mold ive nyore kudhiza, kuitira kuti ipurasitiki irege kunamatira kune mold uye haigone kuvharwa.

Precautions forjekiseni moldpolishing ndezvi:

(1) Kana gomba idzva rekuumbwa richitanga kugadzirwa, nzvimbo yebasa ichatanga kutariswa, uye nzvimbo yacho ichacheneswa neparafini, kuitira kuti dombo remafuta rirege kunamira netsvina uye nokudaro kurasikirwa nebasa rekucheka.

(2) Zviyo zvakakashwa zvichakuyiwa zvine kuoma kutanga uye zviri nyore kugaya, kunyanya kune mamwe makona akafa akaoma kugaya, pasi pacho panotanga kukuyiwa;

(3) Mamwe maworkpiece anogona kunge aine zvidimbu zvakati kuti zvakaunganidzwa pamwechete kuti zviporiswe.Chekutanga, geya zviyo zvakakasharara kana spark zviyo zveimwe workpiece zvakasiyana, wobva wagaya ese maworkpiece pamwe chete kuti utsvedzerere.

(4) Pazvishandiso zvine ndege hombe kana ndege yepadivi, shandisa dombo reoiri kukuya zviyo zvakakasharara wobva washandisa simbi yakatwasuka pakuongorora kufambiswa kwechiedza uye kuyerwa kutarisa kuti pane kusaenzana here kana kuti undercut.Kana paine chero undercut, zvinokonzeresa kuomerwa mukudonhedza kana kunetsa kwezvishandiso.

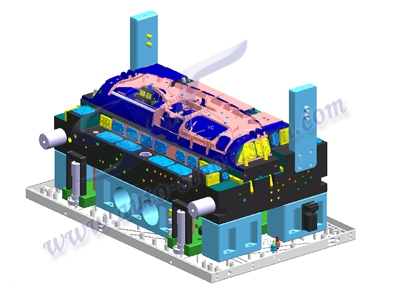

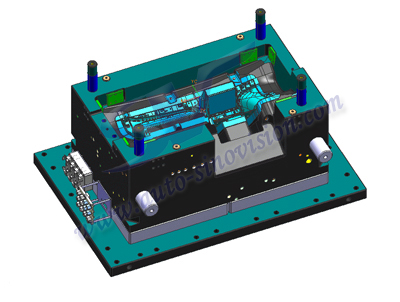

Injection molding processing mugadziri

(5) Kuti udzivise kuterera kune mamiriro ekuti dhizaini rakagadzira bhagi kana mamwe mabhandi epamusoro anoda kuchengetedzwa, blade yesaha inogona kushandiswa kupeta kana sandpaper inogona kushandiswa kunamira pamupendero, kuitira kuti uwane yakanakira kudzivirira maitiro.

(6) Dhonza iyo mold ndege kumashure uye mberi, uye isa mubato weiyo dhizaini seyakadzikama sezvinobvira, isingapfuuri 25 °;Nemhaka yokuti mutsetse wacho wakakurisa, simba racho rinorohwa kubva kumusoro kusvika pasi, izvo zvinotungamirira nyore nyore kune mitsetse yakawanda yakaoma pane workpiece.

(7) Kana nzvimbo yebasa yakasvibiswa nemhangura yemhangura kana bamboo sheet yakatsikirirwa nejecha, sandpaper haifaniri kunge yakakura kudarika nzvimbo yechishandiso, kana zvisina kudaro inokuya kunzvimbo isingafaniri kukuyiwa.

(8) Chimiro chechigadziro chekukuya chinofanira kunge chiri pedyo nechimiro chepamusoro pevhu, kuitira kuti ive nechokwadi chokuti workpiece haina kukanganisa nekukuya.

Semuyenzaniso,mapurasitiki emagetsi emidziyo yemagetsi, plastikimidziyo yezvokudya, etc. Kana pfungwa dziri pamusoro dzakaitwa zvakanaka, kutaridzika kwekupenya kwejekiseni mold kuchave kwakanaka kwazvo.

Nguva yekutumira: Oct-14-2022